Revolutionizing Warehousing: The Comprehensive Guide to Pallet Strapping Machines

A pallet strapping machine is a specialized device designed to efficiently secure goods on pallets by applying straps, bands, or belts made from materials like plastic, polyester, or steel. These machines automate the strapping process, streamlining what was once a labor-intensive task. They come in various types, such as semi-automatic or fully automatic, and function by tensioning, sealing, and cutting the strapping material. Pallet strapping machines are essential in warehouse operations, offering benefits such as increased efficiency, improved safety, product protection, and cost savings by minimizing material wastage. They find widespread use across industries, ensuring the secure transport and storage of goods while optimizing the packaging process.

Understanding Pallet Strapping Machines.

In the world of logistics and warehousing, efficiency and safety are paramount. One of the fundamental components in ensuring the secure transportation and storage of goods is the pallet strapping machine. Often overlooked but essential, these machines play a pivotal role in streamlining packaging processes, ensuring the integrity of palletized goods, and maintaining overall warehouse efficiency.

This comprehensive guide aims to delve into the intricacies of pallet strapping machines, covering their types, functionality, benefits, and their significant impact on modern warehousing operations.

Understanding Pallet Strapping Machines

Pallet strapping machines are devices designed to secure and stabilize goods on pallets by applying straps, bands, or belts made of various materials, including plastic, polyester, or steel. These machines streamline the strapping process, automating what was once a labor-intensive and time-consuming task.

Types of Pallet Strapping Machine

Pallet strapping machines come in various types, each designed to suit different operational needs and production requirements in industries where goods are secured on pallets. Here are some common types of pallet strapping machines:

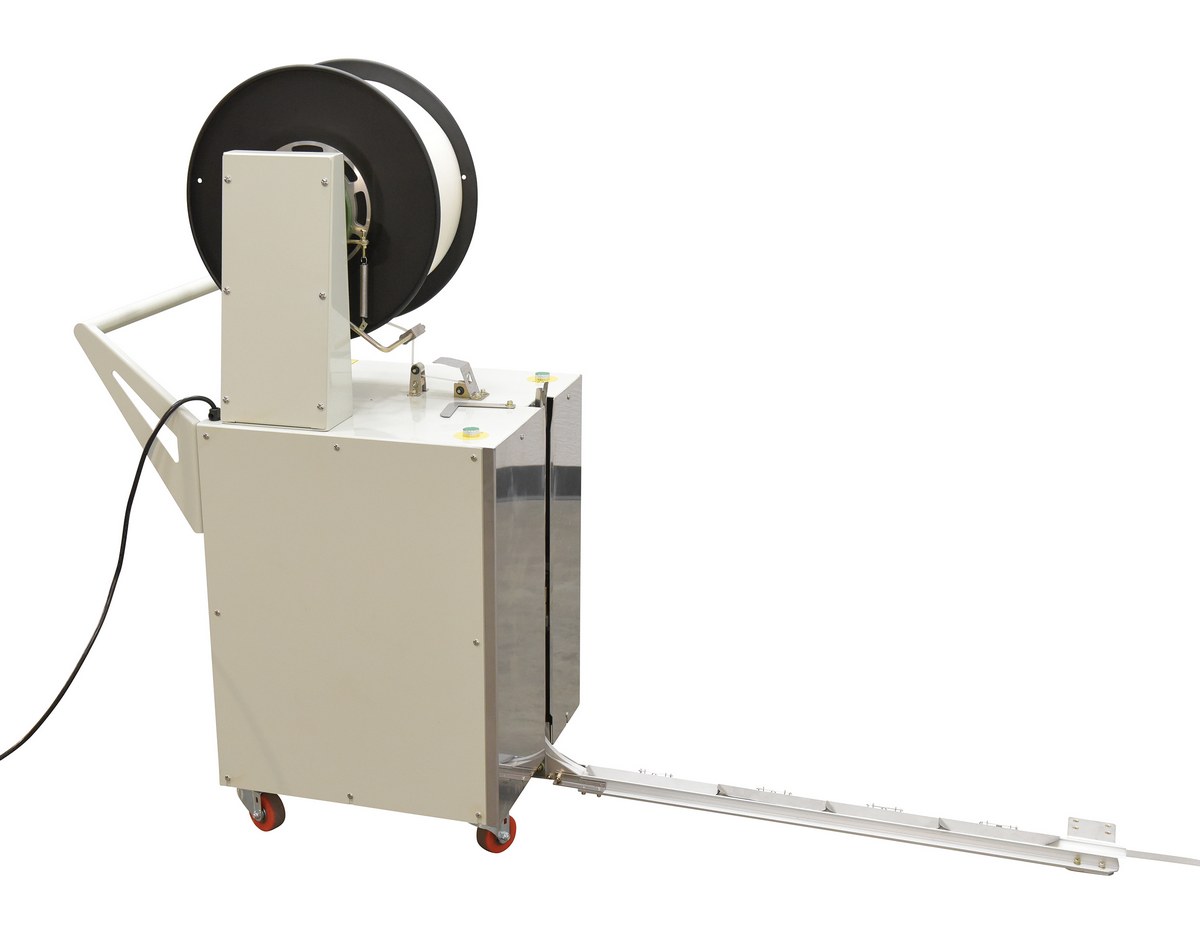

- Semiautomatic Strapping Machines:

- Features: These machines require manual placement of the strapping around the pallet, but the tensioning, sealing, and cutting of the strapping are automated.

- Operation: An operator manually feeds the strapping material around the pallet, and the machine takes over for tensioning, heat sealing or friction welding, and cutting the strap.

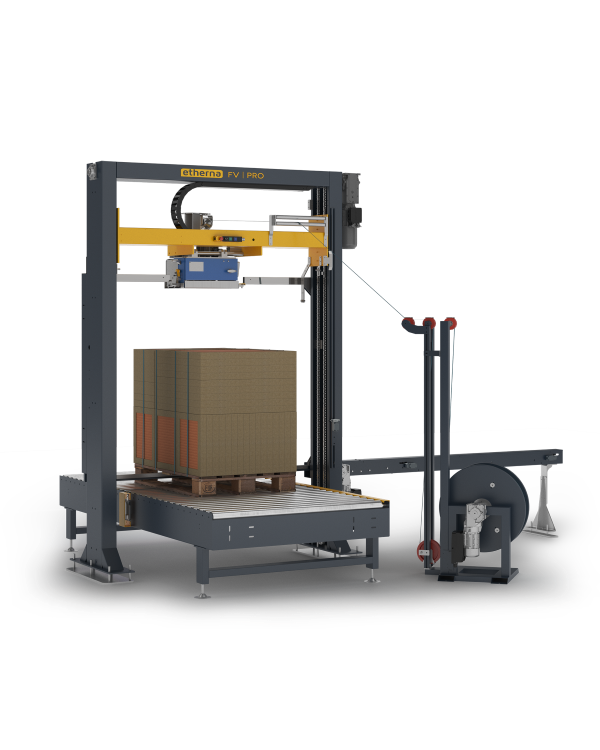

- Automatic Strapping Machines:

- Fully Automated: These machines are designed to automatically detect the dimensions and position of the pallet, applying strapping without the need for manual intervention.

- Sensors and Controls: Automatic strappers use sensors to detect the pallet and various controls for automated strapping operations.

- Reel Dispenser Machines:

- Feeding Mechanism: These machines dispense the strapping material automatically. They might be standalone units or part of semi or fully automatic machines.

- Continuous Feeding: Reel dispenser machines feed strapping material continuously for uninterrupted strapping operations.

- Side-Seal Strapping Machines:

- Sealing Mechanism: Unlike traditional strappers that seal from the bottom, side-seal strapping machines seal the strapping material on the side, allowing for a flat package surface.

- Ideal for Bundles or Flat Packages: These machines are particularly useful for bundling flat packages or goods where a bottom seal might not be feasible.

- Vertical Pallet Strappers:

- Orientation: These strappers are designed to strap pallets in a vertical position, securing the goods on the pallet as it stands upright.

- Space-Efficient: Suitable for warehouses with limited floor space or those requiring a vertical strapping approach.

- Portable or Handheld Strapping Tools:

- Battery-Powered or Manual: These are portable strapping tools used manually by operators to strap individual packages or smaller loads.

- Flexibility: They offer versatility and flexibility, allowing for strapping in various locations within a warehouse or on the go.

- Robotic Pallet Strapping Systems:

- Automated Robotics: These systems use robotic arms or machinery to handle and strap palletized goods automatically.

- Highly Automated: They integrate seamlessly into production lines and are capable of handling a high volume of strapping requirements.

Functionality and Operation

Pallet strapping machines typically consist of a strapping head, a track for the pallet to move along, and controls for adjusting tension, sealing, and cutting the straps. The process involves:

- Tensioning: The strapping material is pulled around the pallet, ensuring a tight fit to secure the load.

- Sealing: Heat sealing or friction welding ensures the straps are joined securely.

- Cutting: Excess strap length is trimmed off after sealing.

These machines are adaptable to different pallet sizes and are adjustable for varying tension requirements based on the product being strapped.

Benefits of Pallet Strapping Machines

The integration of pallet strapping machines offers several advantages to warehouse operations:

- Enhanced Efficiency: Automating the strapping process reduces labor costs and significantly speeds up the packaging process, allowing for higher throughput.

- Improved Safety: Manual strapping can lead to injuries. Pallet strapping machines mitigate these risks, promoting a safer work environment.

- Product Protection: Strapping secures goods to pallets, reducing the risk of damage or shifting during transport or storage.

- Cost Savings: By minimizing material wastage and ensuring optimal use of strapping materials, these machines reduce operational costs.

Impact on Modern Warehousing Operations

The advent of pallet strapping machines has revolutionized warehousing operations. They have become a vital component in modern supply chain management, contributing to:

- Faster Throughput: With their automation and speed, pallet strapping machines contribute to quicker turnarounds and increased productivity in warehouses.

- Accurate Strapping: These machines ensure consistent and reliable strapping, reducing the margin of human error often encountered in manual processes.

- Adaptability: Pallet strapping machines are versatile and adaptable, catering to a wide array of industries, from food and beverage to manufacturing and logistics.

Advantages of Pallet Strapping Machines

- Efficiency: Pallet strapping machines significantly increase the efficiency of the packaging process by automating what was once a labor-intensive and time-consuming task. They work faster than manual strapping, allowing for higher throughput in a shorter time frame.

- Reduced Labor Costs: Automation reduces the need for manual labor, thereby cutting down on workforce expenses. This frees up labor to focus on other essential tasks within the warehouse.

- Improved Safety: These machines reduce the risk of workplace injuries associated with manual strapping. Workers are less exposed to potential strains and injuries from repetitive motions involved in manual strapping processes.

- Product Protection: Strapping secures goods to pallets, minimizing the risk of damage or shifting during transportation or storage. This results in fewer damaged goods and greater customer satisfaction.

- Cost Savings: Pallet strapping machines reduce material wastage by efficiently using strapping materials. They also help in cost savings by enhancing the overall productivity and decreasing the need for rework due to improperly secured pallets.

- Consistency and Reliability: Automated strapping machines ensure uniform and reliable tensioning, sealing, and cutting of straps, minimizing errors commonly associated with manual processes.

Disadvantages of Pallet Strapping Machines

- Initial Investment: Acquiring a pallet strapping machine involves an initial capital investment that might be substantial. This could be a barrier for smaller businesses or those with budget constraints.

- Maintenance and Repairs: Like any machinery, pallet strapping machines require regular maintenance to function optimally. There are costs associated with upkeep and occasional repairs, which add to the overall ownership costs.

- Training and Technical Know-How: Proper training is necessary for operating these machines effectively. This might require additional time and resources to ensure that staff are adequately trained in the operation and maintenance of the equipment.

- Space and Adaptability: Some pallet strapping machines might require a considerable amount of space. For smaller warehouses or facilities with space limitations, accommodating these machines can be challenging. Additionally, certain machines might not be adaptable to various pallet sizes or specific product dimensions.

- Dependency on Power and Technology: Automated pallet strapping machines are reliant on power and technology. Power outages or technical issues can cause disruptions in the packaging process, potentially impacting overall productivity.

Uses of Pallet Strapping Machines

Pallet strapping machines are versatile tools widely used across various industries due to their efficiency in securing goods on pallets. The uses of these machines are diverse and crucial in modern warehouse and logistics operations:

- Packaging and Shipping: The primary use of pallet strapping machines is in packaging and shipping. They efficiently secure goods to pallets, ensuring safe and stable transportation. This is particularly important for heavy, bulky, or irregularly shaped items that might otherwise shift or get damaged during handling or transit.

- Warehousing: Pallet strapping machines are extensively employed in warehouses for both incoming and outgoing goods. They secure products during storage and can expedite the dispatch process by ensuring quick, reliable strapping of pallets for outbound shipments.

- Manufacturing: In manufacturing industries, these machines secure finished products for storage or shipping. They also play a role in securing raw materials or components on pallets, streamlining the supply chain within manufacturing facilities.

- Retail and Distribution Centers: Pallet strapping machines are vital in retail and distribution centers where a high volume of goods needs to be quickly and securely packed for distribution to stores or customers.

- Food and Beverage Industry: Within the food and beverage industry, pallet strapping machines secure perishable items, ensuring they remain intact during transit. They also assist in maintaining hygiene standards, particularly when using appropriate strapping materials suitable for food-grade environments.

- Logistics and Freight Handling: Pallet strapping machines are extensively used in the logistics and freight industry, aiding in securing and stabilizing cargo for shipping by various transportation modes, including trucks, trains, and ships.

- E-commerce and Fulfillment Centers: With the rise of e-commerce, pallet strapping machines are integral in fulfillment centers. They expedite the packaging of orders for shipping, ensuring that products are secured efficiently and dispatched promptly to meet customer demands.

- Building and Construction Materials: Pallet strapping machines secure construction materials like bricks, tiles, and other building supplies on pallets, ensuring safe and organized transport and storage.

- Paper and Print Industry: In the paper and print industry, these machines are used to secure paper rolls and printed materials, preventing damage during handling and transport.

- Pharmaceuticals and Chemicals: Pallet strapping machines assist in securing sensitive and often hazardous materials in the pharmaceutical and chemical industries, ensuring safe and stable transport and storage.

Effects of Pallet Strapping Machines

Pallet strapping machines have various effects on warehouse operations and the supply chain as a whole, impacting efficiency, safety, cost-effectiveness, and overall productivity. Here are some of the key effects of utilizing these machines:

- Increased Efficiency: Pallet strapping machines significantly increase the efficiency of the packaging process. These machines automate the strapping process, reducing the time and labor required for securing goods on pallets. Consequently, the overall throughput and productivity of a warehouse or distribution center are notably enhanced.

- Enhanced Safety: Automation reduces the manual handling of strapping, lowering the risk of workplace injuries associated with repetitive motion or heavy lifting. This creates a safer work environment for employees, minimizing the potential for strains, sprains, or accidents related to manual strapping activities.

- Product Protection: The primary function of pallet strapping machines is to secure goods to pallets, minimizing the risk of damage or displacement during transit or storage. This protection ensures that the products remain intact and undamaged, reducing financial losses due to damaged goods.

- Cost Savings: By reducing labor costs, minimizing material wastage, and ensuring efficient use of strapping materials, pallet strapping machines contribute to cost savings in warehouse operations. This efficiency can lead to a reduction in operational expenses and an increase in the overall profitability of the business.

- Consistent and Reliable Strapping: Automated strapping machines ensure uniform tensioning, sealing, and cutting of straps, resulting in consistent and reliable strapping. This minimizes the risk of errors and inconsistencies commonly associated with manual strapping processes.

- Quicker Turnaround Times: With the automation and speed of pallet strapping machines, the time required to prepare goods for shipment or storage is significantly reduced. This leads to faster turnaround times and enables businesses to meet tighter deadlines and customer demands more effectively.

- Improved Inventory Management: Properly secured pallets lead to better inventory management. Goods that are well-strapped and secure are less likely to be damaged or lost during handling or transit, leading to a more accurate inventory count and reducing the need for constant rechecking or rework.

- Environmental Impact: Effective use of strapping materials and reduction in material wastage due to precise strapping applications contribute to a more eco-friendly operation. This could reduce the environmental impact of excess packaging materials.

- Adaptability and Versatility: Pallet strapping machines are adaptable to various pallet sizes, different product dimensions, and different materials. This versatility makes them suitable for use across a wide range of industries, from food and beverage to manufacturing and logistics.

Environmental Impact on Pallet Strapping Machine

The environmental impact of pallet strapping machines, as with any industrial machinery, is multifaceted and involves several considerations:

- Material Efficiency: Pallet strapping machines contribute to environmental sustainability by promoting material efficiency. They help optimize the use of strapping materials, ensuring that only the necessary amount is used to secure goods on pallets. This reduces material waste, minimizing the environmental impact associated with excess packaging materials.

- Reduced Packaging Waste: Properly secured goods on pallets reduce the likelihood of damage during transit. This can lead to a decrease in product and packaging waste, as well as a reduced need for excessive secondary packaging materials, thereby positively impacting environmental sustainability.

- Recyclability of Strapping Materials: Many pallet strapping materials, such as certain types of plastic straps or bands, can be recyclable. Pallet strapping machines, by efficiently using these materials, contribute to the potential recycling efforts in the supply chain, reducing the overall environmental burden associated with single-use packaging materials.

- Energy Efficiency: Some modern pallet strapping machines are designed with energy-efficient features. These machines optimize power consumption, leading to reduced energy usage and, subsequently, lower environmental impact in terms of energy consumption and carbon emissions.

- Eco-Friendly Strapping Materials: The choice of strapping material used in these machines can significantly impact the environment. Some industries are moving towards more eco-friendly strapping materials, such as biodegradable or recycled straps, reducing the environmental footprint associated with the manufacturing and disposal of strapping materials.

- Reduced Transportation-Related Emissions: Properly secured pallets lead to decreased product damage during transit. This results in fewer returns or replacements, reducing the frequency of transportation for damaged goods and subsequently reducing emissions related to transportation.

- Lifecycle Impact: The overall environmental impact of pallet strapping machines also involves considering their entire lifecycle, from manufacturing to usage and disposal. Efforts to design machines with durability, recyclability, and reduced environmental impact throughout their life cycle can further mitigate their environmental footprint.

Frequently Asked Questions FAQ

What is a pallet strapper?

A pallet strapper, often referred to as a pallet strapping machine or pallet banding machine, is a specialized device used to securely strap or band goods, products, or packages to a pallet. This machine is designed to efficiently and effectively apply strapping material, such as plastic, polyester, or steel bands—around the products loaded on a pallet, ensuring stability and security during handling, storage, and transportation.

Pallet strappers come in various types and configurations, including semi-automatic and fully automatic models. These machines streamline the strapping process by automating the tensioning, sealing, and cutting of the strapping material, which is then wrapped around the products on the pallet.

How does a pallet strapper work?

A pallet strapper, also known as a pallet strapping machine, functions by automating the process of securing goods or products on a pallet using strapping material. These machines come in various types, such as semi-automatic and fully automatic models, but the general working principle involves the following steps:

- Positioning the Pallet: The pallet with the goods to be strapped is placed on the platform or conveyor of the pallet strapping machine.

- Feeding the Strapping Material: The machine either dispenses the strapping material automatically or requires manual loading of the strapping material, depending on the specific model.

- Wrapping and Tensioning: The strapping material is pulled around the products on the pallet using a feeding mechanism. It is then tightened to the desired level of tension, ensuring the goods are secured firmly.

- Sealing and Cutting: Once the strapping is wrapped and tensioned properly, the machine seals the strap, typically through a method such as heat sealing or friction welding. The excess strapping material is then cut off, leaving the strap securely fastened around the products on the pallet.

How do you use a pallet strapping tool?

Using a pallet strapping tool typically involves several steps to efficiently and securely strap goods onto a pallet. There are different types of strapping tools, including manual strapping tools and battery-powered hand-held strapping tools. Here is a general guide on how to use a manual pallet strapping tool:

1. Prepare the Strapping Material:

- Ensure that you have the appropriate strapping material (commonly plastic or polyester strapping) and the strapping tool at hand.

2. Secure the Pallet:

- Place the goods or products onto the pallet and arrange them in the desired manner for strapping. Ensure they are properly positioned and stable.

3. Thread the Strapping Material:

- Insert the end of the strapping material through the tool's strapping track or feedwheel, depending on the specific design of the tool.

4. Tension the Strapping:

- Use the strapping tool to pull the strapping material around the products on the pallet. Apply tension manually by using the tensioning mechanism or by hand, ensuring the strap is tight and secure.

5. Seal and Cut the Strapping:

- Once the strapping material is tensioned adequately, use the strapping tool to seal the strap. This can be done using a sealing method specific to the tool, such as heat sealing, friction welding, or using metal seals.

- After sealing, cut off any excess strapping material using the cutting mechanism of the tool.

6. Repeat for Multiple Straps:

- If multiple straps are required for additional security or to secure different parts of the load, repeat the threading, tensioning, sealing, and cutting steps for each strap.

7. Inspect and Verify:

- Once the strapping is completed, inspect the strapped goods to ensure that the strapping is secure and that the products are stable on the pallet.

What is pallet strapping made of?

Pallet strapping, also known as banding or pallet banding, can be made from various materials. The choice of strapping material depends on factors such as the type of products being secured, the mode of transportation, and the desired level of strength and security required. Common materials used for pallet strapping include:

- Plastic: Polypropylene (PP) and Polyester (PET) are the most widely used plastic materials for strapping. They offer flexibility, moderate strength, and resistance to moisture. Polypropylene is often used for lighter loads, while Polyester offers higher tensile strength and is suitable for heavier loads or products that need greater stability.

- Steel: Steel strapping provides very high tensile strength and is well-suited for heavy-duty applications. It's more rigid and has excellent resistance to cuts and abrasion. Steel strapping is commonly used for heavy or rigid loads that require extreme security during transportation.

- Composite or Corded Strapping: These strapping materials are a combination of different elements. Composite strapping usually comprises a mix of polyester and other materials, providing a balance between strength and flexibility. Corded strapping is made of several cords, offering high tensile strength and resistance to splitting.

The pallet strapping machine stands as a testament to the continuous evolution of warehousing technology. Its ability to streamline operations, enhance safety, and protect goods has made it an indispensable asset in modern supply chains.

As logistics and warehouse operations continue to evolve, the importance of these machines will only grow. The efficiency, safety, and cost-effectiveness they offer have already made them a staple in industries relying on palletized goods.

By understanding the types, functionality, benefits, and the impact of pallet strapping machines, businesses can make informed decisions to integrate this technology, further optimizing their warehouse processes and contributing to a more efficient and secure supply chain ecosystem.